Hi Everyone,

In this week’s tech article, I’m going to show you how to run your LS turbo engine… or any LS engine for that matter, in closed-loop operation on the stock ECM using just one of the factory narrowband oxygen sensors. This works perfectly if you have an LS turbo engine and want to install a single narrowband O2 sensor in the downpipe of the turbo.

Usually, the factory computer needs to see valid inputs from both upstream O2 sensors before switching to closed-loop operation. But there is a way we can wire one sensor to both inputs to fool the ECM into thinking that there are two upstream O2 sensors, and allow operation on closed-loop mode at cruise and part throttle.

If you prefer to watch a video on this topic, you can see how I did this on my truck at this link:

Why do I want my ECM to run in Closed-Loop?

In open-loop mode, the ECM isn’t getting any feedback from the O2 sensors to tell it if the air/fuel mixture is lean or rich. Unless your tune is dead-on, your AFR will probably be a little off. I typically tune the VE table conservatively, so my tune will usually be a bit rich in open-loop. Also, unless your compensation tables are set up perfectly, the AFR ratio can change as the temperature goes up or down.

In closed-loop mode, the ECM gets feedback from the factory narrowband O2 sensors and senses whether the air/fuel ratio is lean or rich. Based on this information, it adjusts the injector pulse width to maintain the correct air/fuel ratio at idle, cruise, or part throttle, even if your tune isn’t perfect or conditions change.

Wiring Changes Required

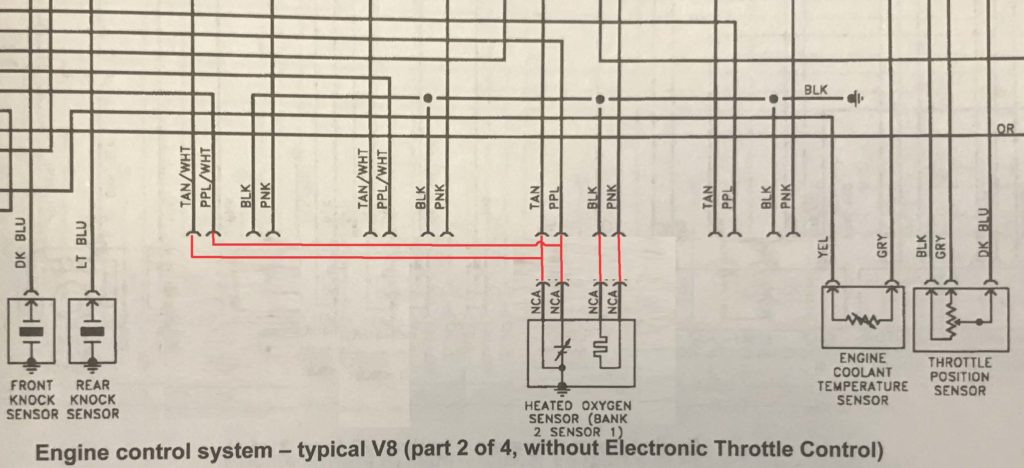

Here’s a wiring diagram for the narrowband O2 sensors the way they come from the factory:

And here’s how we want it to be wired when we’re done:

Again for more details, you can check out the video I made covering this topic. I’ll embed it at the end of this article.

Changes Required in HP Tuners

In my example I’m working on the P01 ECM in my 2000 Silverado, but P59’s and other ECM’s should be similar.

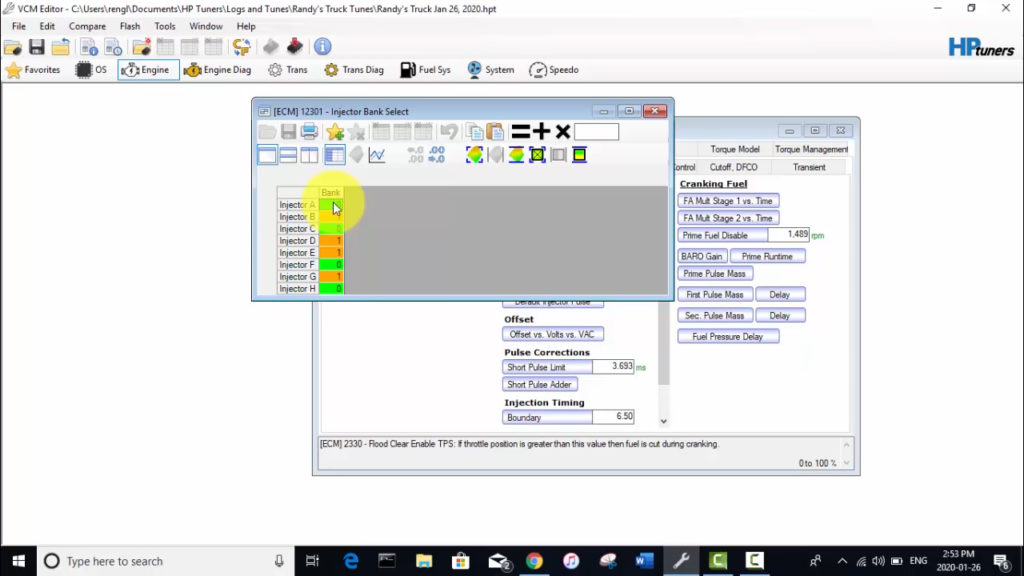

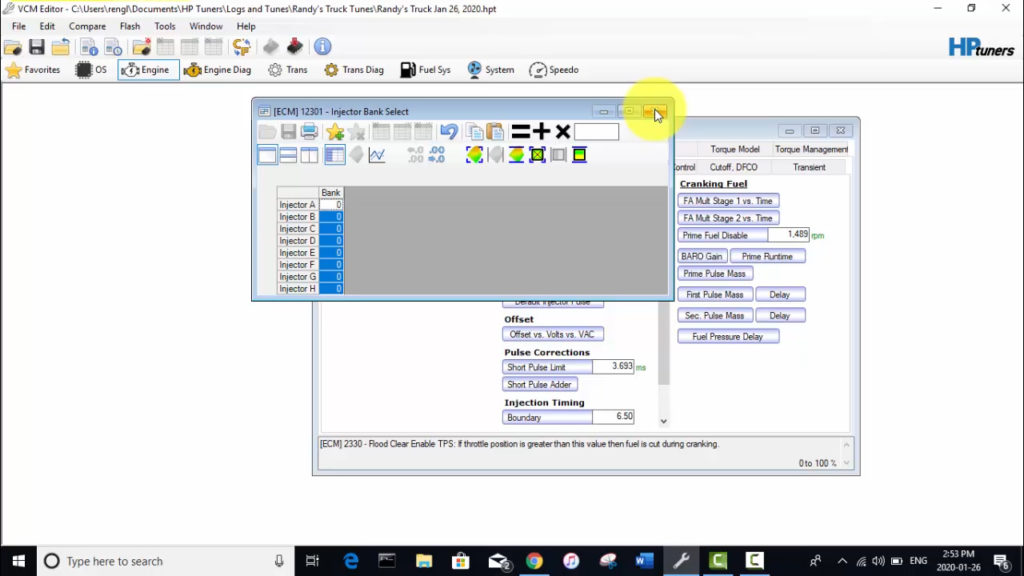

First, go into the Engine>Fuel>General tab and click on the “Injector Bank Select” table. Set all of the values in this table to zero.

Here’s what it looks like in the stock table:

Here’s what it looks like after I’ve changed it:

If the rest of your tune is stock, that should be all you need to do. In my case, I had made some changes previously to force the ECM into Open-loop mode since I didn’t have any of the factory O2 sensors installed.

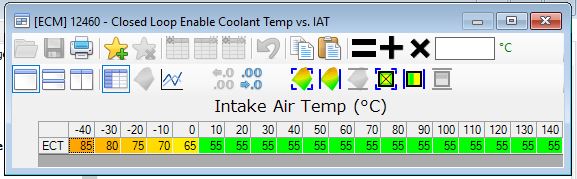

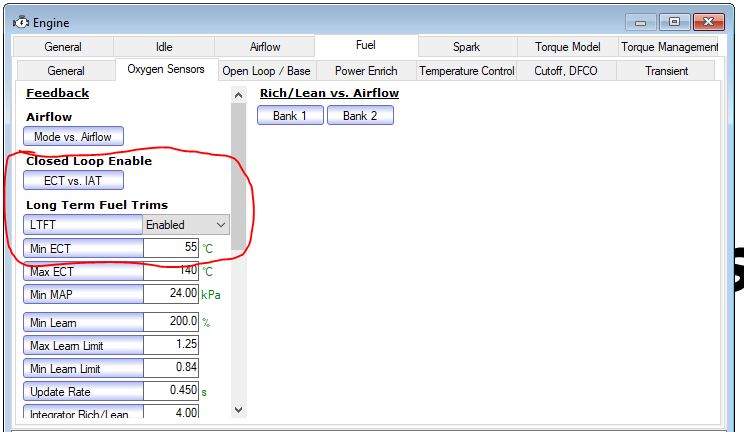

To change it back to function in open loop mode, I had to go to the Engine>Fuel>Oxygen Sensors tab and change the values in the ECT vs. IAT table back to stock.

I also changed the LTFT option back to “Enabled” and set the minimum ECT back to 55 degrees.

That’s all there is to it, you’re ECM should now function with only one O2 sensor installed in the downpipe of the turbo.

Here’s the video I made demonstrating how I did it on my truck:

Have a great week everybody, stayed tuned because next week we’ll be talking about the evolution of the 4.8, 5.3 and 6.0L LS-based Vortec truck engines through Gen 3 and Gen 4.

Bye for now,

Randy (Lowbuck LS)

did you ever take it to the track and what happened?? doing the exact same hing but trying to decide what tuner to use . any suggestions ??

Hey I appreciate all the info I have learned on this page but I was just wanting to make sure . It is necessary to Make the changes to the dtcs for this to work? Planning on putting a turbo on my ls swapped c1500 later on this year .thanks