In this weeks post, we’re going to talk about the evolution of the LS-based Vortec Chevy 4.8, 5.3 and 6.0L truck engines through Gen 3 and Gen 4. We’ll cover the following topics:

- which ones came with drive by

cable throttle bodies - which ones came with drive by

wire throttle bodies - which ones had 24x reluctor

wheels - which ones had 58x reluctor

wheels - which ones had flex-fuel

- which ones had active fuel

management/displacement on demand - which ones have variable valve

timing - the difference between AFM/DOD

and VVT - which ones used return style

fuel systems and which ones were returnless - which ones had iron blocks

- which ones had aluminum blocks

- which cylinder heads came on

each engine - which cylinder heads are most

desirable, and which ones to stay away from - help you choose a suitable

donor for your LS swap or LS turbo project, and which ones to avoid.

As usual, I want my content to be accurate, and I do my best to make sure it’s technically correct, but if you notice anything that isn’t correct, please let me know by commenting below or sending me an email at randy@lowbuckls.com.

But first, let’s touch on what came before these LS-based truck engines. Hot rodding seems to go in phases. We’re right in the middle of the “LS swap the world” phase, but when hot rodding first got started, the go-to engine was the flathead Ford V8.

Then for a good 50 years, the go-to engine for hot rodders was the small block Chevy. It was introduced in 1955 and stayed in production in various forms until the early 2000s. It was swapped into all kinds of different vehicles because it was a compact and versatile engine with lots of options for aftermarket parts.

But it did have some shortcomings, and in 1997 Chevy introduced the LS1 engine in the Corvette. The LS1 was an all-aluminum 345HP 5.7L engine that was a brand new design from the ground up. The LS1 had several improvements that addressed some of the weaknesses of the small block Chevy.

- The most significant

improvement is the strength of the bottom end. Due to the Y-block design and

the six-bolt main caps with a cross-bolted design (4 bolts go through the cap

vertically, and two bolts go horizontally through the block wall into the

bearing cap), the LS blocks keep the crankshaft rigid and stable even at high

power levels. The iron-block truck engines are even stronger than the aluminum

engines, but you have to live with a block that is about 100 pounds heavier

than its aluminum counterpart. - Chevy also moved the cam

further away from the crankshaft to allow a crankshaft with a 4.00″ stroke

to be installed with no machine work or modifications. They also increased the

diameter of the cam bearing journals to 55mm up from 47mm on the SBC, which

allows a higher lift cam to be installed and helps with the stability of the

valve train because the camshaft is stiffer. - Chevy also switched to a

distributorless coil-near-plug ignition system and multi-port fuel injection,

with a coil and injector for each cylinder. This makes these engines very

tuneable, especially when combined with aftermarket tuning software such as HP

Tuners or EFI Live. It is also easy to adapt stand-alone engine management

systems such as the Holley Terminator X system.

In 1999, Chevy introduced the Vortec line of LS-based truck engines, which were based on the LS1 architecture but had an iron block instead of an aluminum one. The Vortec engines came in 4.8, 5.3 and 6.0L displacements.

The 4.8L Vortec Engines

Let’s start by looking at the 4.8L engines. The 4.8L engine that was released in 1999 was the LR4 engine and can be identified by having a V as the 8th digit of the VIN. It was produced from 1999 to 2006. In 1999 it was rated at 255 HP, which was only 15 peak HP less than the 5.3L engine, but the 5.3 version does have some extra torque down low. It shares the same block as the 5.3 but has a shorter stroke. Like the LS1, it utilized cathedral port aluminum heads. The heads were either 862 or 706 castings. None of the 4.8L LM4 engines had displacement on-demand, active fuel management, or variable valve timing. The 4.8L engine is sometimes referred to as the ” 4.Great” engine since it responds well to boost and power adders.

In 2000, the LR4 got a cam upgrade, which bumped up the horsepower rating to 270HP. In 2001, they received MLS head gaskets, and the horsepower rating was increased to 285 HP.

The LR4 engines used a 24x reluctor wheel and a 3-bolt camshaft. The 1999 and 2000 engines that came with a manual transmission had a longer crankshaft, so you should stay away from these models if you want to convert them to an automatic.

The early LR4 4.8L engines (1999-2003) were all drive by cable and had a return-style fuel system. In 2004 they were all changed to drive by wire with a returnless fuel system, except for the Van models, which stayed with the return style, drive by cable system until 2007. None of the LR4 4.8L engines had the flex-fuel capability.

In 2007, Chevy updated the 4.8L to a Gen 4 design with the LY2 RPO code, which can be identified by the C as the 8th digit of the VIN. It was produced from 2007 to 2009. This was still an iron block, aluminum headed engine. The LY2 is an excellent engine! Because it’s a Gen 4, it has stronger rods and a beefier bottom end than the earlier LR4 4.8L engines. It also came with the 799 heads which flow better and have bigger valves than older 706/862 heads. It also doesn’t have any of the fancy, unnecessary stuff yet like active fuel management/displacement on demand or variable valve timing. It does have a 58x reluctor wheel, so if you’re going to install a Terminator or other engine management system, you need to order one that’s designed for the 58x reluctor wheel. Basically, the LY2 4.8L engine is a great engine to look for as a junkyard donor engine.

In 2010, Chevy introduced the L20 4.8L engine, identified by an A as the 8th digit of the VIN. It was produced from 2010 to 2017. Like the LY2, it is a Gen 4 design that features an iron block with aluminum cylinder heads. The heads were either 799 or 243 castings, which are both desirable cylinder heads. It also introduced variable valve timing and flex-fuel capabilities to the 4.8L engine, which means if you’re doing a cam swap, you’ll have a bit of additional cost and work for an AFM/DOD/VVT delete kit.

Active Fuel Management/Displacement on Demand and Variable Valve Timing

This probably a good time to talk about active fuel management/displacement on demand vs. variable valve timing.

AFM/DOD is a feature that is designed to improve fuel economy by deactivating cylinders when they are not needed. This involves using solenoids and special lifters.

VVT is a feature that optimizes the cam timing of an engine by retarding or advancing the whole camshaft to optimize the efficiency of the engine, depending on where it is operating in the power curve.

The 5.3L Vortec Engines

Now let’s talk about the 4.8L engines bigger brother, the 5.3. As I mentioned earlier, the 4.8 and 5.3 share the same block in the older Gen 3 models, but the 5.3 has a longer stroke. The 1999 5.3L models were released as the LM7, which is the engine I have in my truck. Being a Gen 3 design, the rods and bottom end aren’t quite as stout as the later Gen 4 models. The LM7 can be identified by the T in the 8th digit of the VIN. The LM7’s were produced from 1999 to 2006.

Like the LR4, the LM7 uses a 24x reluctor wheel and a three-bolt cam. Also, like the LR4 engines, the power rating was increased during its production run. The 1999 LM7 engines were rated at 270 HP. In 2000, they got a cam upgrade like the LR4’s did, and the power rating was increased to 285 HP. In 2004 the power output was bumped up yet again to 295 HP. It also uses the 706/862 cylinder heads.

In the trucks, the LM7’s were drive by cable with a return style fuel system from 1999 to 2003. Some SUV models switched to drive by wire sooner, though. In 2004 all of the LM7’s except for the van models were switched to drive by wire with returnless fuel systems.

The L59 is a flex-fuel version of the LM7 that was produced from 2002 to 2007. It can be identified from the Z in the 8th digit of the VIN.

In 2005, Chevy produced an all-aluminum, high-performance version of the 5.3L designated the L33 RPO code, which can be identified by the B in the 8th digit of the VIN. This engine was still a Gen 3 engine and was only in production for a couple of years from 2005 to 2007. These engines had higher compression because of their flat-topped pistons. They also came with a better camshaft and the desireable 243 and 799 cylinder heads. This engine was also known as the Vortec 5300 HO model and was rated at 310 HP.

Also in 2005, Chevy began transitioning the 5.3 engine to Gen 4 with the release of the LH6 engine in it’s SUV lineup, identified by the letter M in the 8th digit of the VIN. The early versions of the LH6 were kind of a hybrid between the Gen 3 and Gen 4 engines. Some guys refer to these engines as the Gen 3.5. They have the good Gen 4 rods and upgraded internals but still used a 24x reluctor with the black crank sensor. (Newer 58x engines had a grey crank sensor.) The LH6 engines used an aluminum block and were basically a replacement for the LM4 engine. I’m also pretty sure the LH6 was the first LS-based truck engine to offer active fuel management. In 2007 the LH6 became a full-fledged Gen 4 engine with the 58x reluctor wheel. It remained in production until 2009. The LH6 engines used the good 243/799 cylinder heads.

In 2007, Chevy released the LY5 5.3L engine, identified by the letter J in the 8th digit of the VIN. This was an iron block engine to replace the old Gen 3 LM7 engine. These engines had active fuel management and came with the good 243/799 cylinder heads. They remained in production until 2009. Chevy also released a flex-fuel version of this engine with the RPO code LMG, which can be identified by a 0 in the 8th digit of the VIN. The LMG version remained in production until 2014.

Also released in 2007 was an aluminum blocked counterpart to the LY5, which was designated the LC9, which can be identified by the number 3 in the 8th digit of the VIN. It was in production until 2011. It had active fuel management and was flex-fuel capable. In the 2010 and newer model years, the LC9 also had variable valve timing. The LC9 engines also came with 799/243 heads.

In 2008 and 2009, Chevy also had a simpler 5.3L engine designated the LH8, which can be identified by the letter L in the 8th digit of the VIN. This was an aluminum blocked engine that had the 243/799 heads but didn’t have AFM/DOD or VVT. This transitioned into the LH9 from 2010 to 2012, identified by a letter P in the 8th digit of the VIN. It still used 799/243 heads but also utilized variable valve timing and had flex-fuel capability.

Chevy also used a 5.3L engine that was only in vans produced from 2010 to 2014, known as the LMF engine, identified by a number 4 in the 8th digit of the VIN. This was an iron blocked engine with VVT, flex-fuel, and 243/799 heads.

The 6.0L Vortec Engines

The Gen 3 version of the 6.0L engine was first released as the LQ4 RPO code in 1999, designated by a letter U in the 8th digit of the VIN. The early LQ4 engines (1999 and 2000) were the only LS based engines to come with an iron cylinder head (cylinder head casting numbers 373 and 873.) These early LQ4’s also had a longer crankshaft, which makes them incompatible with later transmissions. Starting in 2001, the LQ4 switched to an aluminum cylinder head like the rest of the LS family and switched to a shorter crankshaft as well. The newer heads were 317 or 035 casting numbers, which featured larger valves like the 799 and 243 heads, but also larger combustion chambers, which means the static compression ratio will be lower unless the heads are milled to increase the compression ratio. This makes these heads slightly less desirable than the 243/799 heads. Like the rest of the Gen 3 truck engines, the LQ4 used a 24x reluctor wheel and a three-bolt cam and didn’t have AFM/DOD/VVT.

In 2002, Chevy released a high output version of the 6.0 known as the LQ9 or Vortec Max engine. This engine can be identified by a letter N in the 8th digit of the VIN. The LQ9 was still an iron block, aluminum headed engine and was rated at 345 HP. It also used the 317/035 heads but had a higher compression ratio due to the use of flat-topped pistons.

Like the rest of the Gen 3 truck engines, the early models of the LQ4 and LQ9 were drive by cable and had return style fuel systems. That changed to drive by wire with returnless fuel systems in 2003, with the exception of the van lineup. The LQ4 and LQ9 engines were produced until 2007.

In 2007, Chevy transitioned the 6.0L into the Gen 4 model with the introduction of the LY6. The LY6 can be identified by a letter K or N in the 8th digit of the VIN. The LY6 had an iron block but used a rectangular port aluminum head with a casting number of 823. I’m pretty sure it was the first truck engine to utilize a rectangular port head instead of a cathedral port head. The head also had valves that were larger than both the 317 heads used on earlier 6.0L engines and the 243/799 heads used on the 4.8/5.3L engines. The LY6 engines were rated at 364 HP and utilized VVT but not AFM or flex-fuel. The LY6 was used in trucks until the 2010 model year.

GM also released an aluminum blocked counterpart known as the L76. The L76 6.0L engine featured AFM and VVT but not flex-fuel. The L76 also made use of the 823 casting rectangular port heads. The L76 truck engine was used from 2007 to 2009, and it was also installed in some cars.

In 2010, Chevy introduced the L96 version of the 6.0L, identified by a letter G in the 8th digit of the VIN. This was an iron block engine that was used up until 2017. It continued to use the 823 rectangular port aluminum head. It featured VVT and flex-fuel but didn’t utilize AFM/DOD.

Chevy also used an aluminum blocked, cathedral port version of the 6.0 in 2008 and 2009, this engine was known as the LFA RPO code and was identified by a number 5 as the 8th digit of the VIN. This engine used the 243/799 cathedral port heads and was used in hybrid trucks and SUVs. From 2010 to 2013, they changed this engine to an LZ1 RPO code but it was still mainly only used in hybrid vehicles.

There were a few other LS-based truck engines such as the 6.2 L engines, but my main focus is on the 4.8, 5.3 and 6.0L engines since those are the ones most readily available in junkyards.

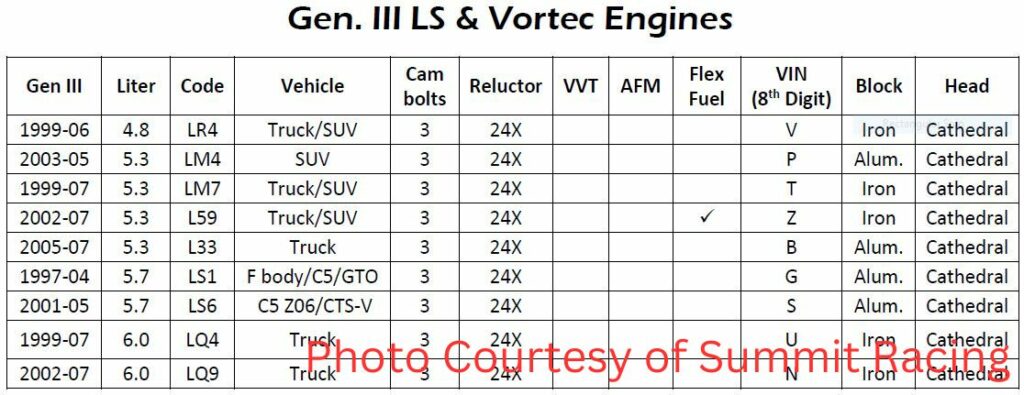

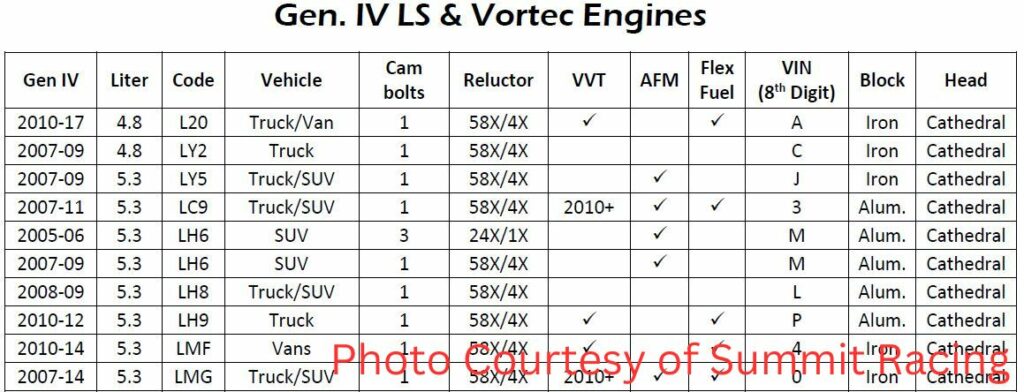

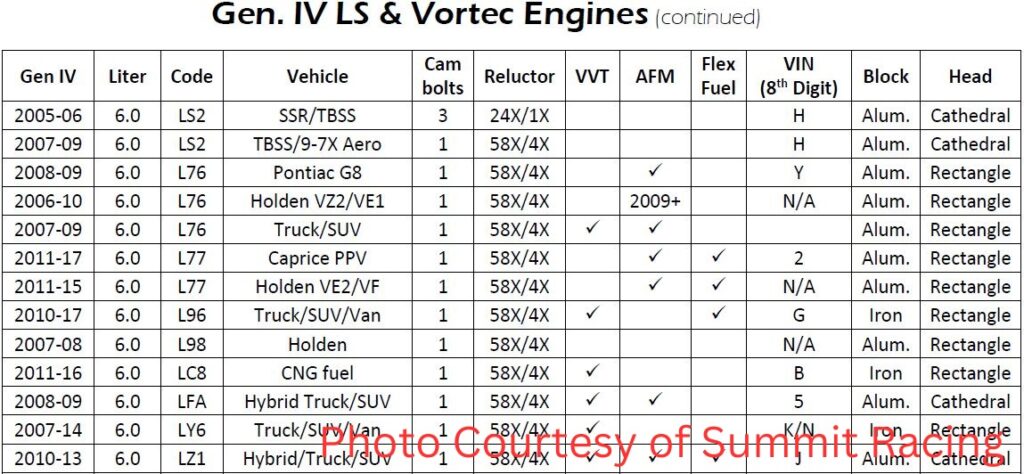

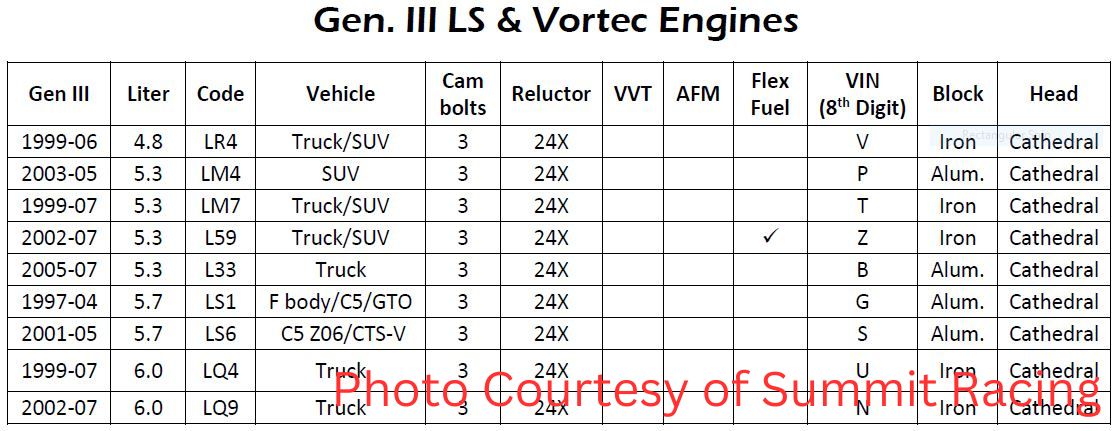

I’m going to include a chart from Summit Racing that breaks down all the information I’ve presented here in a chart form.

The Engines to Stay Away From

In summary, the only engines to really stay away from when you’re hunting for a donor in the junkyard, are the manual transmission 4.8L models from 1999 and 2000, since they have an extended crankshaft. I would also stay away from the 1999 and 2000 LQ4 6.0L engines since they have iron heads and have the weird extended crankshafts too.

Which Junkyard LS Engine Should You Look For?

If you’re not looking for more than about 500-600 horsepower, any of the Gen 3 engines such as the 4.8L LR4, 5.3L LM7, or 6.0L LQ4 or LQ9 will do fine. If you plan on pushing the power levels beyond that, you should either look for a Gen 4 engine, or think about at least using Gen 4 rods in your Gen 3 engine, or installing some stronger aftermarket rods or a whole rotating assembly. The Summit Racing Pro LS rotating assemblies look pretty solid, I haven’t used them myself yet, but I plan to at some point in the future when I’ve reached the limit of the Gen 3 rods in my LM7. The L33 is also an engine that lots of guys look for, but I’d stay with an iron block engine if you’re going to be using a power adder.

For Gen 4 engines, the LY2 and L20 4.8L engines are a good choice. If you want a 5.3, look for an LY5, LMF, or LMG model if you’re using a power adder. For a 6.0, I’d look for an L96 if I was using a power adder. If you’re planning on staying NA, any of the aluminum block engines will work fine.

This has gotten a little long, so I’m going to wrap it up for this week, but we’ll talk to you guys again soon.

Bye for now,

Randy

Hello Randy, I have a 2000 Silverado 4×4 with a 4.8, bought this truck new and now has 210K miles and still runs well but problem is it’s gutless, love this truck which is in mint condition and have been looking for ways to get to get more pep out of it without making it into a race truck. Any suggestions would be appreciated. Thx Randy.

Would probably be a good idea to look around for a 5.3 or a 6.0, at least a short block. If you want to go the extra mile and the cylinders are ok, buy a set of replacement flat top pistons off eBay or Amazon for $200 or less, swap in some cheap Gen IV rods that go for $150 while you’re in there if you can afford it, justbmake sure that the pistons and rods you buy are both press fit or floating pin. Those sites even sell full packages with all the gaskets, fasteners, bearings, lifters, trays, rings and so on for a mild rebuild, some include the pistons, some include 1218 springs and the Elgin 228/230 cam. If your truck has 862/706 heads stick with those, if they are rough there are online rebuild services you can send yours in or just order a finished set, they’re only $500-600, those are the best head for performance in a truck, they only produce 9hp fewer at the very peak between 6000-65000 and produce 10-20 more TQ across 1500-1800 rpms in the low to mid rpms than 799/243 heads, a TBSS intake goes for $150 and produces 15hp and TQ more than the early truck, add a 92mm TB for $100-200, long tubes for those trucks are a little as $200 stainless with 1.75″ primaries, depending where your compression ends up you can use 0.027″ head gaskets to increase your compression 0.7:1 or reduce compression 0.3:1 with LS9 0.060″ instead of standard 0.051″ as long as you are willing to use 91-93 or E85 with 10.8-11.6 compression is safe, 180 t-stat is a good idea, NG6 tr6 plugs and wires are a good idea, a torque converter with a 2400-3200 stall and possibly running a 3.73 or 4.10 axle instead of your 3.23 or 3.42 gears will make a world of difference, it costs more however a triple disk converter that is capable of lockup under power will make you highway economy better and is stronger while making the truck drive completely different. If you have more money for a truck cam the Truck Norris is above the rest because it has a 107 LSA, if you use the David Vizard 128 formula to spec your cam and have one made with the idea LSA(which will be much tighter LSA than common shelf cams), duration and lift to suit your engine and vehicle your results will be the very best. You can easily assemble your own engine with a used 5.3 or 6.0 while you are still using your truck and could be ready to swap everything out quick over a weekend to avoid downtime. 400whp isn’t excessive or unobtainable and doesn’t have to cost too much if you get creative and shop smartly. It’a gonna feel mean without being too Racey.

Thank you for compiling this info and posting in an easy to follow format.

What about the vortec 7400.no mention in this article about it or the 8100.

That’s because those engines are not based on the LS architecture.

2005-2007 4.8 has gen 4 rods.

Randy, I’m being handed the Keys to a 2009 Chevy Pickup so look for the Letter on the block to know which motor it has? Being a 09 it could have any of the motors is this correct? It reads Vortex when I open the hood am New to the LS and want to put in a 1977 Luv 😆

i Have a 2011 L96

where would you start on something like this, im using it in a 1961 impala, vvt delete?

intake?